In the manufacturing sector, industry professionals employ computer numerical control (CNC) precision machining—an advanced subtractive manufacturing process—to produce highly precise parts and products to extremely tight tolerances. Depending on the part and production specifications, they utilize a variety of different machining equipment and machine tools, all of which are monitored and operated by computerized programs and controls.

Southern Spring & Stamping, Inc. is an expert provider of CNC machining services. Equipped with six decades of experience and state-of-the-art machining equipment, our team has the knowledge, skills, and tools to meet a wide range of CNC precision machining needs.

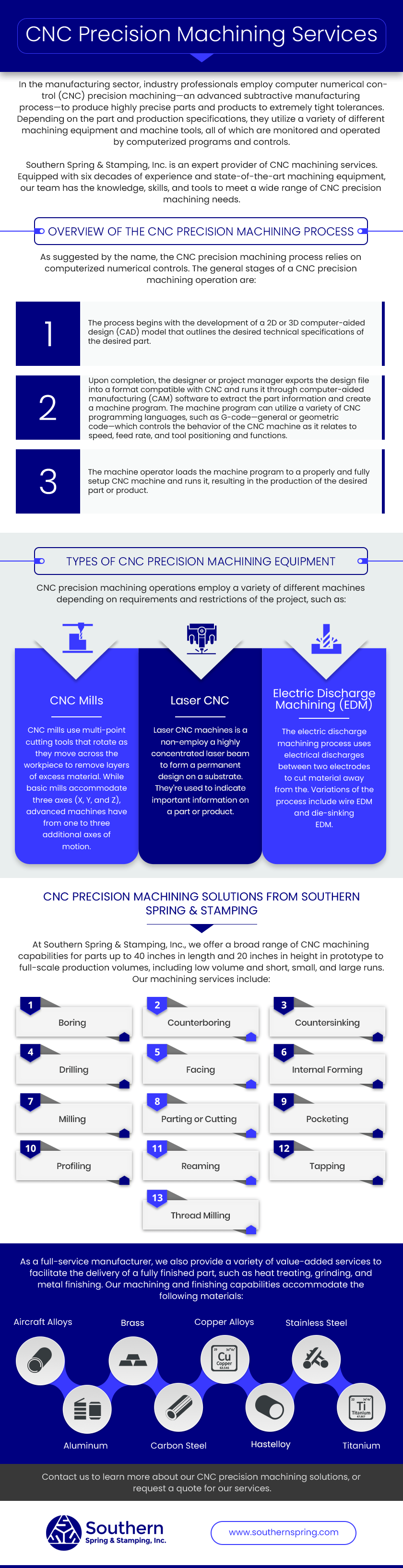

Overview of the CNC Precision Machining Process

As suggested by the name, the CNC precision machining process relies on computerized numerical controls. The general stages of a CNC precision machining operation are:

- The process begins with the development of a 2D or 3D computer-aided design (CAD) model that outlines the desired technical specifications of the desired part.

- Upon completion, the designer or project manager exports the design file into a format compatible with CNC and runs it through computer-aided manufacturing (CAM) software to extract the part information and create a machine program. The machine program can utilize a variety of CNC programming languages, such as G-code—general or geometric code—which controls the behavior of the CNC machine as it relates to speed, feed rate, and tool positioning and functions.

- The machine operator loads the machine program to a properly and fully setup CNC machine and runs it, resulting in the production of the desired part or product.

Types of CNC Precision Machining Equipment

CNC precision machining operations employ a variety of different machines depending on requirements and restrictions of the project, such as:

- CNC mills. CNC mills use multi-point cutting tools that rotate as they move across the workpiece to remove layers of excess material. While basic mills accommodate three axes (X, Y, and Z), advanced machines have from one to three additional axes of motion.

- Plasma cutters. Plasma cutters utilize superheated and ionized gas to cut shapes and designs into and out of the workpiece. They are generally used to process metals but can be used on other types of materials.

- Electric discharge machining (EDM). The electric discharge machining process uses electrical discharges between two electrodes to cut material away from the. Variations of the process include wire EDM and die-sinking EDM.

CNC Precision Machining Solutions From Southern Spring & Stamping

At Southern Spring & Stamping, Inc., we offer a broad range of CNC machining capabilities for parts up to 40 inches in length and 20 inches in height in prototype to full-scale production volumes, including low volume and short, small, and large runs. Our machining services include:

- Boring

- Counterboring

- Countersinking

- Drilling

- Facing

- Internal forming

- Milling

- Parting or cutting

- Pocketing

- Profiling

- Reaming

- Tapping

- Thread milling

As a full-service manufacturer, we also provide a variety of value-added services to facilitate the delivery of a fully finished part, such as heat treating, grinding, and metal finishing. Our machining and finishing capabilities accommodate the following materials:

- Aircraft alloys

- Aluminum

- Brass

- Carbon steel

- Copper alloys

- Hastelloy

- Stainless steel

- Titanium

Armed with 4-axis machining equipment, an automated pallet changing system, and customized programming tools, our team meets customer demand with cost-effective, quality parts and prompt service. We apply quality-certified methods to all of our production runs, employing statistical process controls to monitor accuracy, minimize variability, and maintain product consistency. We maintain ISO 9001 certification and can meet or exceed the strictest industry standards.

Contact us to learn more about our CNC precision machining solutions, or request a quote for our services.