The process of metal stamping parts is essential to countless industries, such as military, medical, aerospace, hydraulic, and oil manufacturers industries. Metal stamping has also seen growth in industries producing heat exchangers, knives, and firearms.

Metal stamping is a process that forms sheet metal or slit metals into two-dimensional parts shaped for a variety of applications. Our team at Southern Spring and Stamping offers a full suite of metal stamping services, including:

- Blanking

- Drawing

- Forming

- Piercing

We work with you create a range of custom metal-stamped parts, we also work with you to create custom metal stamping solutions for those seeking a more personalized approach. Here, we’ve outlined some of our most popular processes.

Types Of Custom Metal Stamping Processes

Progressive Die Stamping

Progressive die stamping helps create metal parts with complex geometry, typically reducing labor costs and production times associated with fabricating complicated parts.

Progressive die stamping moves a workpiece through a number of stations with specialized functions. Each station adds to the work of the previous one, resulting in a completed part at the end of the process. This method incorporates several stamping techniques, including punching, coining, bending, and other methods of modifying raw metal, and it operates via an automatic feeding system.

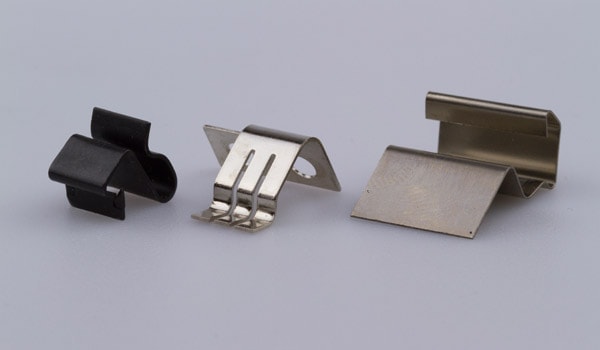

Drawn Stamping

The drawn process radially draws a sheet metal blank into a forming die using a mechanical puncher. Components that need several different diameters benefit from drawn processes, which create parts to the desired specifications more cost effectively than turning processes.

Fourslide And Vertislide Forming

Fourslide and Vertislide forming operates similarly to the progressive die metal stamping process, but it uses additional forming stations to accommodate client specifications. A metal stamping die shapes parts from the inserted sheet metal, and a die component knows as a punch helps with the actual shaping operation itself. The punch pushes the sheet metal through the die to provide operators with a finished shape.

Request A Custom Metal Stamping Quote

custom metal stamping by southern spring & stamping, inc.

Southern Spring can accommodate low- and high-volume orders with efficiency and ease. Regardless of volume size, our customers can expect impeccable quality and tight tolerances for every part that comes out of our factories. We possess the most advanced equipment on the market, and we continually reevaluate our technology as industry needs grow and change.

We can manufacture several varieties of high-compression springs and unlabeled stamp parts to suit your company’s needs. We also perform laser and assembly services that will help you cut down on the time and effort you spend on fabrication and production.

Stress-free Stamping At Southern Spring & Stamping, Inc.

We at Southern Spring continue to rapidly expand our metal stamping services to meet our clients’ needs. Since 1957, we’ve continued to cement our place as your one-stop shop for high-quality, precision stamping products.

Contact us today or request a free quote to find out how our craftsmanship can make a difference in your organization.