About CNC Machining

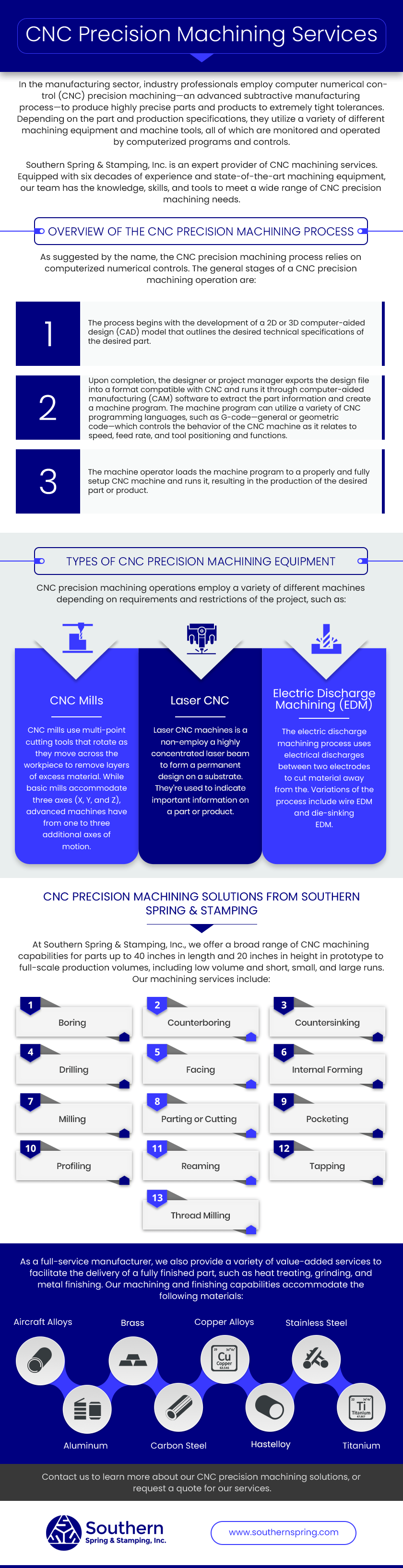

Computer Numerical Control, or CNC machining, uses computer software to control the movement of a range of sophisticated factory tools and machinery. The specialized software programs used in CNC machining improve manufacturing processes by eliminating the manual operation of machines and enabling processes such as intricate three-dimensional cutting to be completed with a single set of computer prompts.

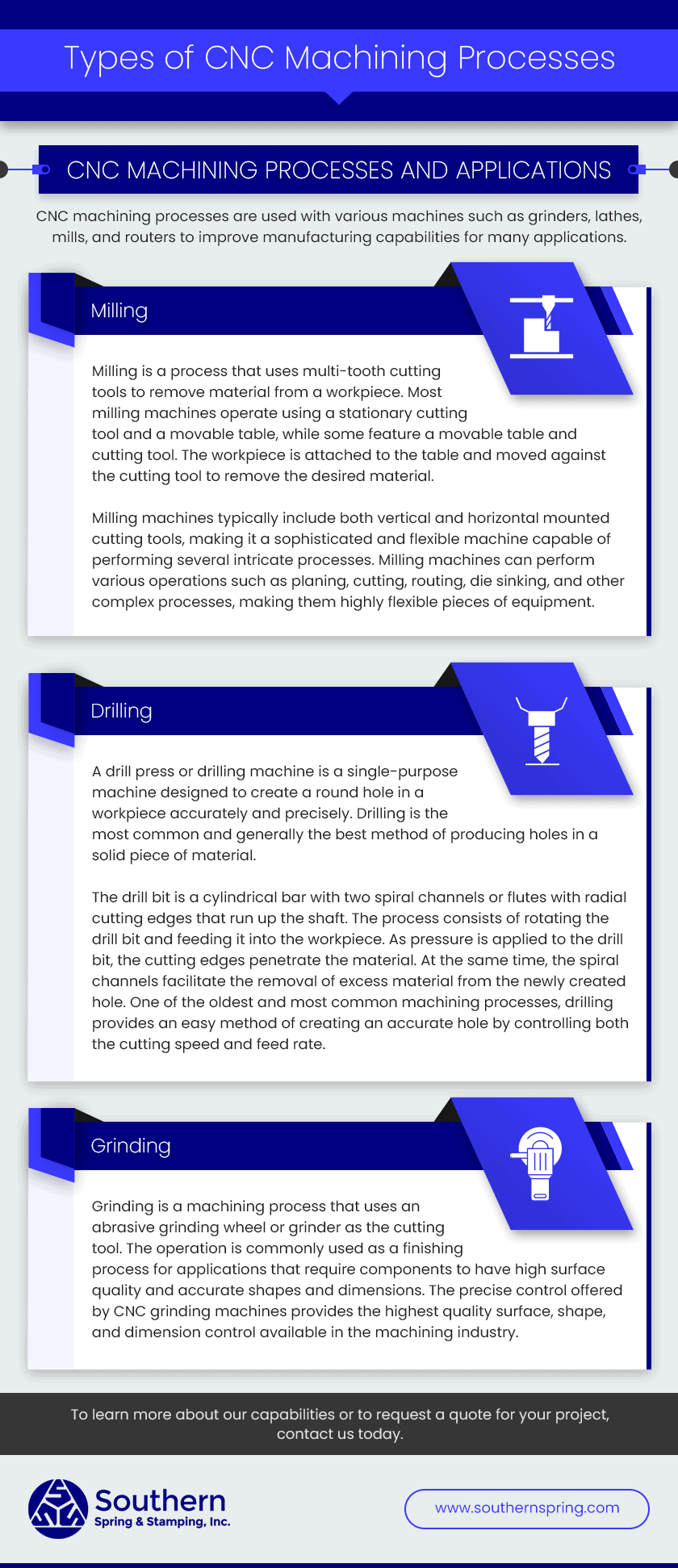

CNC Machining Processes and Applications

CNC machining processes are used with various machines such as grinders, lathes, mills, and routers to improve manufacturing capabilities for many applications. Material selection can also play an important role for certain applications.

Milling

Milling is a process that uses multi-tooth cutting tools to remove material from a workpiece. Most milling machines operate using a stationary cutting tool and a movable table, while some feature a movable table and cutting tool. The workpiece is attached to the table and moved against the cutting tool to remove the desired material.

Milling machines typically include both vertical and horizontal mounted cutting tools, making it a sophisticated and flexible machine capable of performing several intricate processes. Milling machines can perform various operations such as planing, cutting, routing, die sinking, and other complex processes, making them highly flexible pieces of equipment.

Drilling

A drill press or drilling machine is a single-purpose machine designed to create a round hole in a workpiece accurately and precisely. Drilling is the most common and generally the best method of producing holes in a solid piece of material.

The drill bit is a cylindrical bar with two spiral channels or flutes with radial cutting edges that run up the shaft. The process consists of rotating the drill bit and feeding it into the workpiece. As pressure is applied to the drill bit, the cutting edges penetrate the material. At the same time, the spiral channels facilitate the removal of excess material from the newly created hole. One of the oldest and most common machining processes, drilling provides an easy method of creating an accurate hole by controlling both the cutting speed and feed rate.

Grinding

Grinding is a machining process that uses an abrasive grinding wheel or grinder as the cutting tool. The operation is commonly used as a finishing process for applications that require components to have high surface quality and accurate shapes and dimensions. The precise control offered by CNC grinding machines provides the highest quality surface, shape, and dimension control available in the machining industry.

Capabilities of Southern Spring

At Southern Spring & Stamping, we have over 60 years of experience providing custom CNC machined components. Our state-of-the-art facility utilizes the newest and most advanced machining technology available including two Okuma M560-V machining centers, letting us serve a variety of industries by providing precision components in a prompt, cost-effective manner.

Our 4-axis capabilities and customized programming tools enable us to machine all the required features of a component from a single setup. Our CNC machining capabilities, along with our highly skilled and trained workforce, allow us to provide clients with exceptionally fast turnaround and consistent quality components manufactured from a range of metals, including stainless steel, aluminum, aircraft alloys, copper, and many more.

To learn more about our capabilities or to request a quote for your project, contact us today.